WHAT IS DRAIN RELINING?

WHAT IS DRAIN RELINING?

As drainage related problems go, damaged drain pipes rank among the most bothersome of the lot. Apart from the fact that they are notoriously tricky to detect at the outset, leaky drain pipes also damage the environment by polluting the soil.

In the past, the only way to fix damaged drain pipes was the long and expensive process of excavation and replacement. This was a notoriously difficult process as more often than not, the damaged pipes were usually buried metres under the ground. Sometimes buried under infrastructure like roads, driveways or retaining walls.

Today, however, thanks to modern technology, drainage pipes can be fixed via the relatively easier and cheaper method known as drain relining.

PROCESS OF DRAIN RELINING

INSPECTION

The process of drain lining begins with the inspection of drainage pipes. Unlike the old method of drain replacement which involves excavation of pipes, the drain relining process makes use of CCTV survey technology. This inspection determines the location and extent of any damage to the pipes.

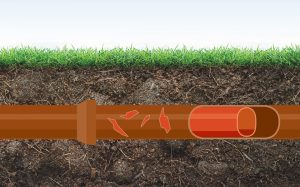

CLEARING OF DEBRIS

After the inspection, the pipes are cleaned to prevent any obstruction during the relining. The intrusions (tree roots for example) are removed using a robotic cutter which can cut through even steel and concrete. After this, a high-pressure water jetter is used to clear the pipe of any debris. This ensures a good bond on the pipe wall.

RE-INSPECTION

Before the new drain liner is fixed, the pipes are inspected once again to ensure all possible intrusions have been removed.

PREPARING THE LINING

The method of relining as well as the exact amount and type of pipelining needed is decided at this stage. This is because different types of liners are used in different situations. More flexible liners, for instance, are used in cases where the pipes are curved as manoeuvrability is required.

THE INSTALLATION

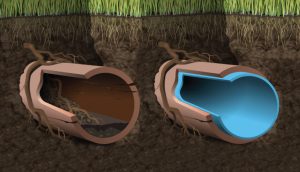

The installation process can be done in two ways. The first is by a process known as inversion. Here, a resin is poured into the drain liner and repeatedly rolled to ensure it is evenly distributed on its body. It is then inserted into the damaged pipe by using inflated airbags to shape the lining to the pipe walls or by using water pressure.

It could also be installed via GFRP UV pipelining. Here, the pipelining is pulled into the damaged pipe by using cables and winches.

Both methods ensure the lining is perfectly fitted to the surface of the pipe. This guarantees effective drainage.

CURING

After installation, comes the curing process. This involves the hardening of the resin to ensure the lining stays in place. When installing via inversion, it can be left to cure by itself, or sped up by running hot water through the pipe. GFRP UV pipes, on the other hand, require UV lighting to cure the lining to full hardness.

FINAL RE-INSPECTION

After the damaged section of the drainage pipe has been fixed, one final inspection is carried out to ensure the pipe is as good as new. This involves visual inspections with CCTV surveys and checks for leaks with leak detection equipment.